What is a slitter rewinder machine?

Introduction

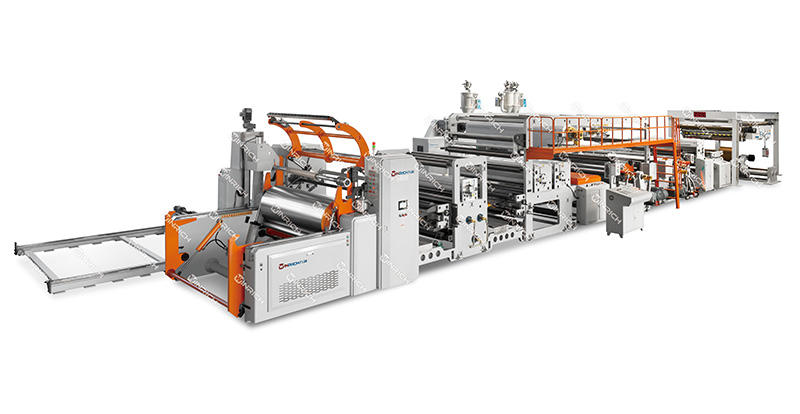

In the manufacturing and packaging industries, efficiency and precision are critical. One machine that plays a vital role in converting large rolls of materials into smaller, more manageable sizes is the slitter rewinder machine. Whether used for paper, film, foil, or non-woven fabrics, slitter rewinders ensure high-speed, accurate cutting and rewinding for various industrial applications.

This article explores the function, types, applications, and benefits of slitter rewinder machines, with a special focus on Paper Slitter and Rewinder systems and Paper Slitting Machine technology. Businesses in printing, packaging, and paper processing will learn why these machines are indispensable in modern production lines.

What Is a Slitter Rewinder Machine?

A slitter rewinder machine is an industrial device designed to cut (slit) large rolls of material into narrower strips and then rewind them into smaller rolls. These machines are widely used in industries such as:

Packaging(plastic films, laminates, labels)

Printing & Paper Converting(newspaper, books, cardboard – making Paper Slitter and Rewinder machines essential)

Textiles(non-woven fabrics, synthetic materials)

Metallurgy (foil, metalized films)

The process involves unwinding, slitting, and rewinding materials with high precision, ensuring minimal waste and maximum efficiency.

How Does a Slitter Rewinder Work?

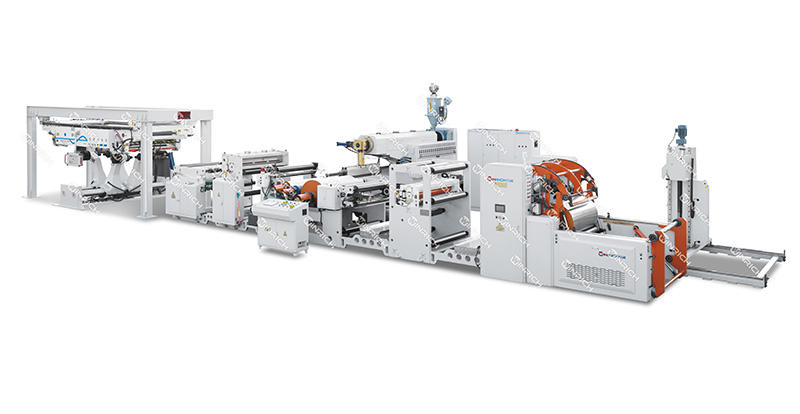

A typical Paper Slitting Machine or general-purpose slitter rewinder operates in three main stages:

1. Unwinding – The master roll (large input roll) is mounted on the machine and fed into the system.

2. Slitting – Sharp blades or laser cutters slit the material into narrower widths according to preset dimensions.

3. Rewinding – The slit strips are rewound into individual smaller rolls, ready for further processing or packaging.

Modern Paper Slitter and Rewinder systems feature automated controls, tension regulation, and defect detection to ensure consistent quality in paper converting applications.

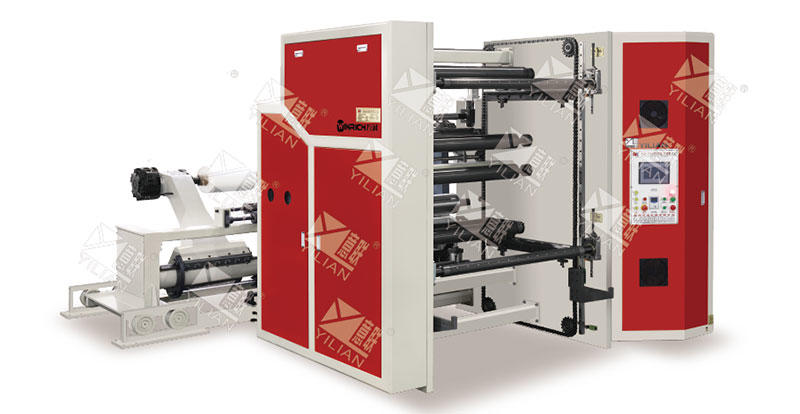

Types of Slitter Rewinder Machines

Different industries require specialized slitter rewinders based on material type and production needs. The most common types include:

1. Razor Blade Slitter Rewinders

Best for thin, flexible materials like films, foils, and lightweight paper.

Uses sharp razor blades for clean cuts.

2. Shear Cut Slitter Rewinders

Ideal for thicker materials (cardboard, heavy-duty paper – common in Paper Slitting Machines).

Uses rotary blades for precise, burr-free cutting.

3. Crush Cut Slitter Rewinders

Suitable for adhesive tapes and thin plastics.

Uses a hardened steel blade against a rubber roller.

4. Laser Slitter Rewinders

High-precision cutting for sensitive materials.

No physical contact, reducing contamination risks.

For paper-based industries, Paper Slitter and Rewinder machines often use shear or razor cutting depending on thickness and finish requirements.

Key Benefits of Using a Slitter Rewinder

1. Increased Efficiency – Converts large rolls into multiple smaller rolls in a single pass, reducing downtime (critical for Paper Slitting Machine operations).

2. Precision Cutting – Ensures accurate widths with minimal material waste.

3. Versatility – Handles various materials, from delicate films to rigid paperboard.

4. Automation & Speed – Modern Paper Slitter and Rewinder systems offer high-speed processing with minimal manual intervention.

5. Cost Savings – Reduces labor costs and material waste, improving ROI.

Applications Across Industries

Paper & Printing Industry – Paper Slitting Machines convert large paper rolls into books, magazines, and packaging materials.

Packaging Industry – Processes plastic films, labels, and paper-based packaging.

Textile & Non-Woven – Slits fabrics for medical, hygiene, and industrial uses.

Electronics – Prepares precision films for LCD screens and insulation materials.

For businesses handling paper products, investing in a high-quality High Speed Paper Slitter And Rewinder ensures smooth production flow and consistent output.

Choosing the Right Slitter Rewinder

When selecting a Paper Slitting Machine or general slitter rewinder, consider:

Material Type(film, paper, foil, etc.)

Slitting Method (razor, shear, crush, or laser)

Production Speed & Automation Level

Machine Durability & Maintenance Needs

A well-chosen Paper Slitter and Rewinder can enhance productivity, reduce waste, and improve product consistency.

Conclusion

Slitter rewinder machines, especially Paper Slitting Machines, are essential for industries that rely on roll-to-roll material processing. By enabling precise cutting and rewinding, they optimize production efficiency and reduce costs. Whether for packaging, printing, or paper converting, choosing the right Paper Slitter and Rewinder can significantly impact a company’s operational success.

For businesses looking to upgrade their material handling processes, a modern, automated slitter rewinder is a smart investment that delivers long-term benefits.

Need help selecting the best Paper Slitting Machine for your needs? Contact us today for expert recommendations!