Extrusion in Packaging: A Comprehensive Guide

Extrusion is a fundamental technology in the packaging industry and is widely used to produce flexible, durable and high-performance materials. Among its many applications, extrusion coating lamination plays a vital role in improving the functionality of packaging films, papers and foils. This article will explore extrusion in packaging, focusing on extrusion coating lamination, its advantages and the machinery involved.

I. Understanding Extrusion in Packaging

Extrusion is a manufacturing process that melts and forms plastic raw materials into continuous profiles. In the packaging field, extrusion is mainly used to produce films, sheets and coatings with barrier properties, strength and printability.

There are two main types of e xtrusion in packaging:

1. Blown film extrusion – used to produce plastic films for packaging bags and pouches.

2. Cast film extrusion – used to produce thin and uniform films commonly used in food packaging.

However, one of the most advanced applications is extrusion coating lamination, which combines extrusion with lamination to produce multi-layer packaging materials.

II. What is extrusion coating lamination?

Extrusion coating lamination is a process where a molten polymer layer is applied to a substrate (such as paper, aluminum foil or plastic film) and then bonded to other materials under pressure. This technology enhances the properties of the substrate, including:

Moisture resistance

Heat sealability

Improved barrier properties (oxygen, grease, UV protection)

Increased durability

III. Key steps in extrusion coating lamination:

1. Substrate preparation – The substrate (such as paper or film) is unrolled and cleaned.

2. Polymer extrusion – The resin pellets are melted and extruded through a flat die.

3. Coating application – The molten polymer is applied to the substrate.

4. Lamination – A second laminating film is pressed onto the coated substrate using an **Extrusion coating laminator**.

5. Cooling and winding – The laminate is cooled and wound for further processing.

IV. The role of an extrusion coating laminator

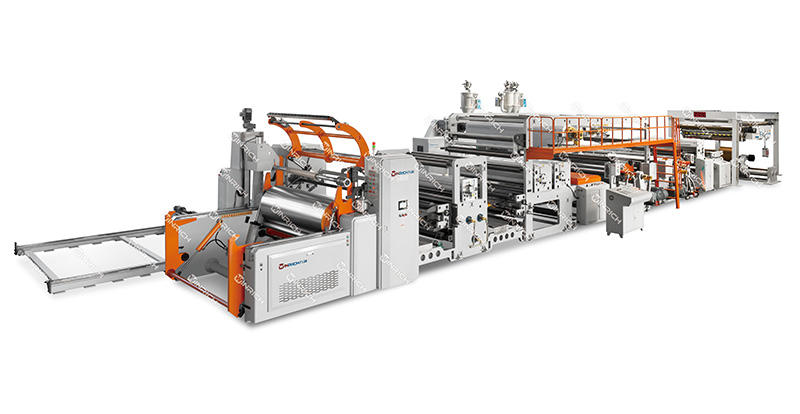

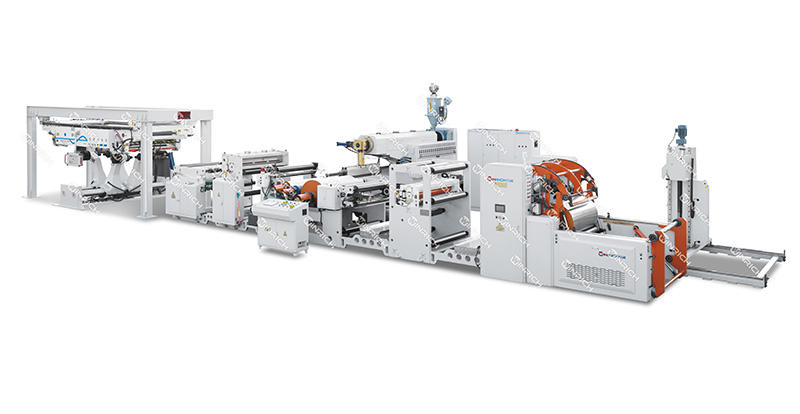

High-performance Extrusion coating laminators are essential for producing high-quality laminated packaging materials. These machines are designed to handle a variety of substrates and polymers, ensuring precise coating thickness and strong adhesion.

Key Features of Extrusion Coating Laminating Machine

High-speed extrusion capability

Precise temperature control to ensure uniform melting

Adjustable layer thickness

Multi-layer laminating options

Extrusion coating laminating process is widely used in:

Food packaging (e.g., snack bags, beverage cartons)

Medical packaging (sterile barrier film)

Industrial packaging (moisture barrier liner)

Consumer goods (flexible packaging bags, labels)

Conclusion

Extrusion technology, especially extrusion coating laminating process, is a game-changer in the modern packaging industry. By utilizing advanced extrusion coating laminating machine, manufacturers can produce high-barrier, durable and cost-effective packaging solutions. As the demand for sustainable and high-performance packaging continues to grow, extrusion coating laminating will continue to play a key role in the industry.