Film Laminating Machine Supplier

Wenzhou Winrich Machinery Co.,ltd is located in Pingyang county,Wenzhou city of Zhejiang Province,China, established in 1996. It covers land area of 15,800sqm.standardized workshop of 11,000 sqm,and holds 50-100 sets machines production every month,which is the largest in Wenzhou.

Company has strong technical strength, sophisticated production equipment, perfect testing means, excellent management level, set the "scientific research, development, sales, service" as one of the joint-stock enterprises.

Company's main products are:extrusion coating and lamination machines, slitter and rewinder, paper cutter and sheeter, which are widely used in paper, cloth, metal foil, plastic bags, non woven fabric and other materials. Machines are pretty popular in Southeast Asia, Middle East, Eastern Europe, South America, Africa and other countries, it also has occupied 80% of Chinese market. Strong technical team, sophisticated production process, perfect testing means, excellent management level, timely after-service, makes it a professional and brand manufacturer of printing and packaging equipment in China.

product description

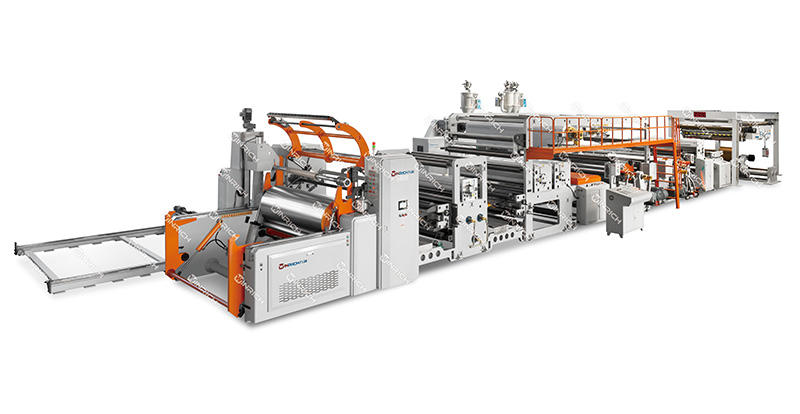

1. SJFM 1000-2000D double mainframe extrusion film laminating machine

Main features:

Sjfm dual host extrusion coating and laminating unit, the absorption of foreign advanced technology, is currently a complete advanced models of double-sided laminating process, the equipment used to need a complete production of double coated paper, or multilayer composite materials such as carton of milk, juice box, beverage box, etc., is an ideal equipment for production of aseptic packaging materials

Main technical parameters:

| type | SJFM-1000 | SJFM-1100 | SJFM-1300 | SJFM-1600 | SJFM-1800 |

| compounding speed | 100-150 | 100-150 | 100-150 | 100-150 | 100-150 |

| net laminating width | 500-900 | 600-1050 | 600-1250 | 800-1550 | 1000-1750 |

| laminating thickness | 0.010-0.1 | 0.010-0.1 | 0.010-0.1 | 0.013-0.1 | 0.013-0.1 |

| laminating layer | 43500 | 43500 | 43500 | 43500 | 43500 |

| extruding quantity | 10-150/20-150 | 10-180/20-180 | 10-200/20-200 | 10-250/30-250 | 10-280/30-280 |

| screw L/D ratio | Φ90 28:1 | Φ95 30:1 | Φ105 30:1 | Φ105 32:1 | Φ110 33:1 |

| power | 110 | 130 | 150 | 180 | 200 |

| overall dimension | 13000×8300×3200 | 13000×8400×3200 | 13000×8600×3200 | 13000×9000×3200 | 13000×9300×3200 |

| SVS1.25-5 | #10 | 5.3mm | 8.1 | 21.2 | 6.5 |

| SVL1.25-5 | #10 | 5.3mm | 9.5 | 21.2 | 6.5 |

| SVS1.25-6 | 43469 | 6.5mm | 9.5 | 21.2 | 6.5 |

| SVL1.25-6 | 43469 | 6.5mm | 12 | 27.2 | 11 |

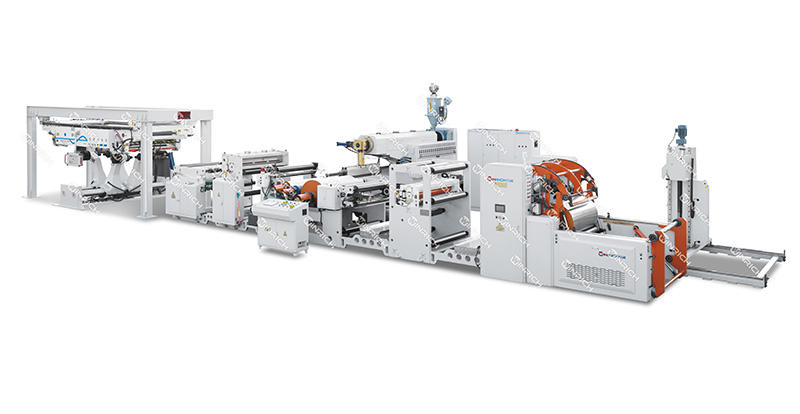

2. SJFM1100-2000M Automatic Multilayers Extrusion Film Coating and Lamination Machine

Main Features:

This series of Extrusion Lamination Machines are mainly paper, plastic film, non-woven cloth or aluminum foil as substrate, by casting a compound into two layer, three layer (sandwich), widely used in food packaging, pharmaceutical packaging and other industries. Such as making a cup, a bowl of instant noodles, feed bags, medical materials, fast food box, non-woven bag. PLC man-machine interface control, machine, electricity, gas, integrated design; high precision Motou, high efficiency, high speed mixed refine screw, swift filter screen changer, 360o second reel; can be equipped with a single extruder. Double screw extruder, multi-stage attack realize multilayer coextrusion.

Main Technical Variables:

| MODEL | SJFM1100-2000M |

| mechanical Specifications | 1100-21000mm |

| max.speed of coating film | 100-150 |

| Suitable coating resin film | PE,PP ,EVA,EAA |

| Suitable base material | PAPER, Glass Net Cloth,NOPP/BOPET,(AL) |

| width of coating film | 1000-2200mm |

| thickness of coating film | 0.012~0.1mm |

| inaccuracy thickness of coating film | ±5mm |

| complex cooling roller | Φ500mm,Φ600mm,Φ700mm |

| screw specification | (L/D)Φ90:33,Φ100:33,Φ110::33: |

| main unwinding diameter | Φ800-1300mm |

| diameter of auxiliary unwinding | Φ600mm |

| diameter of rewinding | Φ800-1300mm |