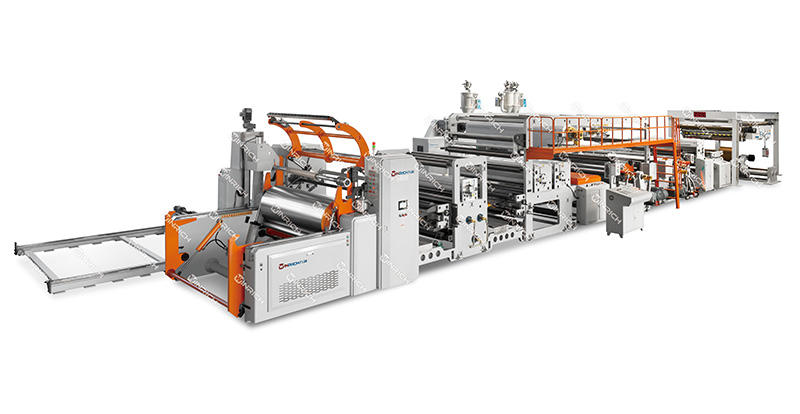

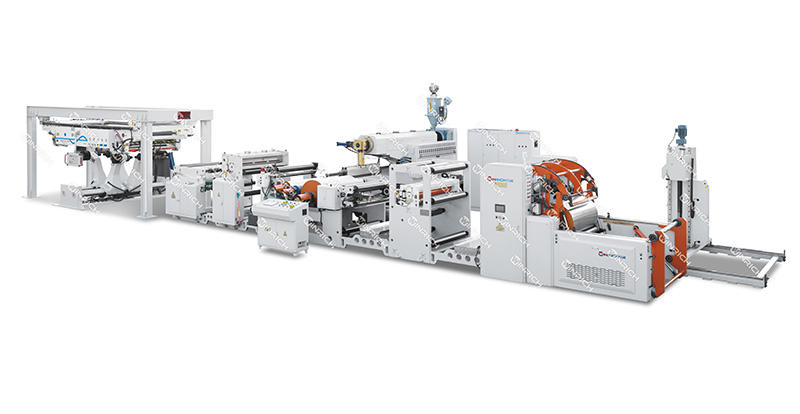

WSFM1100 Series Laminating Machine Product Introduction

WSFM1100-2000C automatic high-speed green environmental protection laminating machine and WSFM1100-2000B automatic high-speed hydraulic shaftless double-sided laminating machine are mainly used in paper cups, paper bowls, instant noodle bowls and other products.

Its mechanical characteristics are centralized control of PLC man-machine interface, integrated design of machine, electricity and gas. It adopts high-precision edgeless imported original die, high-speed and efficient mixing device (Italian technology). It has a quick change mechanism, equipped with a dry compound machine system and a dry compound machine function. Can be equipped with single extruder, double extruder, multi-extruder.

WSFM1100-2000C automatic high-speed green environmental protection laminating machine technical parameters

- Mechanical specifications: 1100/90mm, 1300/100mm, 1500/105mm, 1800/110mm

- Maximum speed of coating film: 150m/min, 180m/min, 200m/min

- Applicable film resin: LDPE, PP, EVA, EAA

- Applicable substrate: BOPP, BOPET, BOPA, CPP, CPE, paper (PAPER), aluminum box (AL)

- Film width: 1100mm, 1300mm, 1500mm, 1800mm

- Coating thickness: 0.012~0.1mm

- Net film thickness error: ≦ ± 5%

- Composite cold roll: Φ500mm, Φ600mm, Φ700mm

- Screw specifications: (L/D) Φ90:33, Φ100:33, Φ105:33; Φ110:33

- Main unwinding diameter: Φ800-1500mm (extra large diameter)

- Auxiliary unwinding diameter: Φ500mm

- Winding diameter: Φ800-1700mm (extra large diameter)

WSFM1100-2000B automatic high-speed hydraulic shaftless double-sided laminating machine technical parameters

- Mechanical specifications: 1100/90mm, 1300/100mm, 1500/105mm, 1800/110mm

- Maximum speed of coating film: 150m/min, 180m/min, 200m/min

- Applicable film resin: LDPE, PP, EVA

- Applicable substrate: BOPP, BOPET, BOPA, CPP, CPE, paper (PAPER),

- Film width: 1100mm, 1300mm, 1500mm, 1800mm

- Coating thickness: 0.012~0.1mm

- Net film thickness error: ≦ ± 5%

- Composite cold roll: Φ500mm, Φ600mm, Φ700mm

- Screw specifications: (L/D) Φ90:33, Φ100:33, Φ105:33; Φ110:33

- Main unwinding diameter: Φ800-1500mm (extra large diameter)

- Auxiliary unwinding diameter: Φ600mm

- Winding diameter: Φ800-1700mm (extra large diameter)