Extrusion Lamination Machine Supplier

Company Profile

Wenzhou Winrich Machinery Co.,ltd is located in Pingyang county,Wenzhou city of Zhejiang Province,China, established in 1996. It covers land area of 15,800sqm.standardized workshop of 11,000 sqm,and holds 50-100 sets machines production every month,which is the largest in Wenzhou.

product description

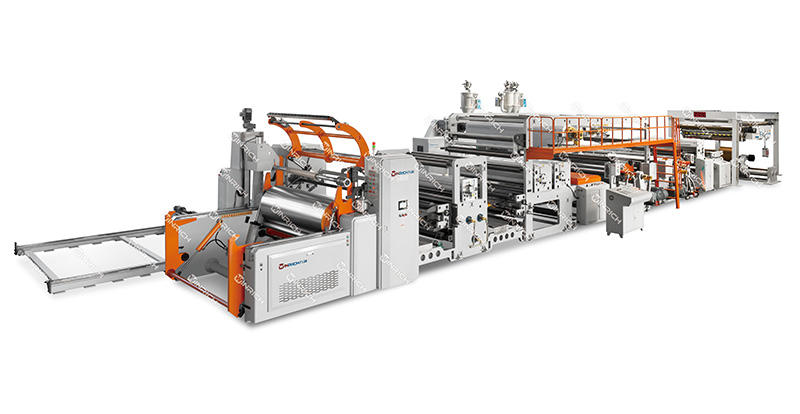

SJFM1100-2000A Extrusion lamination machine

Sjfm series environmental protectional extrusion lamination machine, set unwinding and rewinding, drying, surface treatment,extrusion, compounding, trimming, suction side as a whole;it features with web guiding, corona treatment, line speed, meter counting; automatic tension control, temperature control and other advanced technology. Running speed 100-150m/min.

Features:

1.PLC man-machine interface centralized control, machine, electricity, gas, integrated design.

2 high efficient corona device

3.Easy and quick filter screen exchange

4.Double station unwinding and rewinding, automatic non stop roll exchange

Main technical parameters:

| model | SJFM-800 | SJFM-1100 | SJFM-1300 | SJFM-1600 | SJFM-1800 |

| Width of die | 900mm | 1200mm | 1400mm | 1800mm | 2000mm |

| width of finished product | 400-700mm | 500-1000mm | 600-1250mm | 800-1500mm | 900-1700mm |

| Max. speed | 100-150m/min | 100-150m/min | 100-150m/min | 100-150m/min | 100-150m/min |

| Coating thickness | 0.01-0.1mm | 0.01-0.1mm | 0.01-0.1mm | 0.01-0.1mm | 0.01-0.1mm |

| L/D ratio for screw | Φ80mm×30 | Φ95mm×30 | Φ105mm×30 | Φ120mm×32 | Φ140mm×32 |

| diameter for roll unwinding and rewinding | Φ1300mm | Φ1300mm | Φ1300mm | Φ1300mm | Φ1300mm |

| overall size | 9600×8000×3200 | 9600×8300×3200 | 9600×8600×3200 | 9600×9000×3200 | 9600×9300×3200 |

| L*W*H(MM) | |||||

| power | 60kw | 70kw | 80kw | 100kw | 130kw |

| compounding roller | Φ510mm | Φ510mm | Φ510mm | Φ510mm | Φ610mm |

| applicable for base material | Paper/non woven /PP woven sack,etc | ||||

| Extrusion resin | LDPE、LLDPE、PP、EVA、EAA,etc |

Application:

paper pe coating, woven PP sack lamination, non woven lamination and so on.

It is widely used in disposable paper cup,oil and water proof paper bag, fast food boxes, pp woven bag, non woven vertical bag, baby diaper packing bag, cement bag, ground film, roof radiant barrier product and so on.

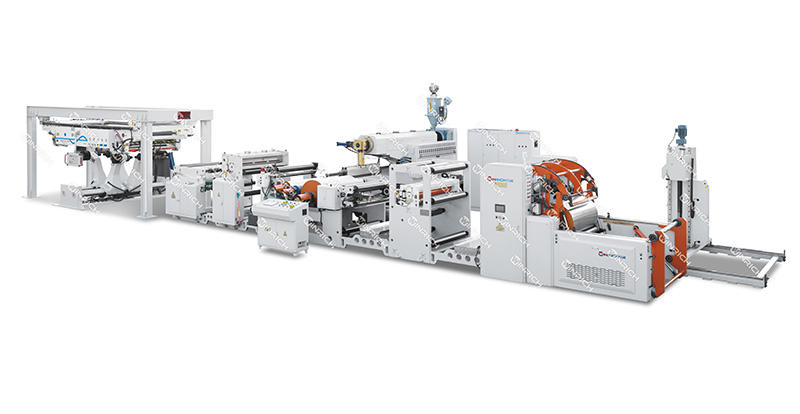

WSFM1100-2000C automatic Extrusion Coating And Laminating Machine

Main features:

1.PLC man-machine interface control, the design of mechanical electrical integration.

2.High precision and imported die head

3.High speed and efficient mixing equipment (Italy technology).

4.Automatic hydraulic filter screen exchange

5.Equipped with dry type composite system, with the function of dry composite machine

6.And can be matched with a single extruder, Twin Extruder, extruder, multilayer coextrusion

The main technical parameters:

| machinery specification | 1100/90mm,1300/100mm ,1500/105mm, 1800/110mm |

| speed of coating film | 150m/min,180m/min,200m/min |

| suitable coating resin film | LDPE,PP, EVA ,EAA |

| suitable base material | BOPP,BOPET,BOPA,CPP,CPE,PAPER,AL |

| width of coating film | 1100mm,1300mm,1500mm,1800mm |

| thickness of coating film | 0.012~0.1mm |

| inaccuracy thickness of coating film | ≦±5% |

| complex cooling roller | Φ500mm,Φ600mm,Φ700mm |

| screw specification | (L/D)Φ90:33,Φ100:33,Φ105:33;Φ110:33 |

| main unwinding diameter | Φ800-1500mm |

| diameter of auxiliary unwinding | Φ500mm |

| diameter of rewinding | Φ800-1700mm |

Application:

For producing Single Side PE Coated Paper Cup Paper,Paper Bowl Paper,Instant Noddle Bowl Paper etc.